What is the difference between hydrophilic PP, SMP, SM, SSPP in medical non woven fabrics?

S stands for spunbond, spunbond nonwoven fabric;

M is a melt-blown non woven fabric.

PP stands for polypropylene

In the non woven fabric process, there is a sandwich material called SMS, which is a spunbond, spunbond and spunbond structure. This material has both good spunbond strength and good barrier properties of melt spunbond, and is often used in medical supplies.

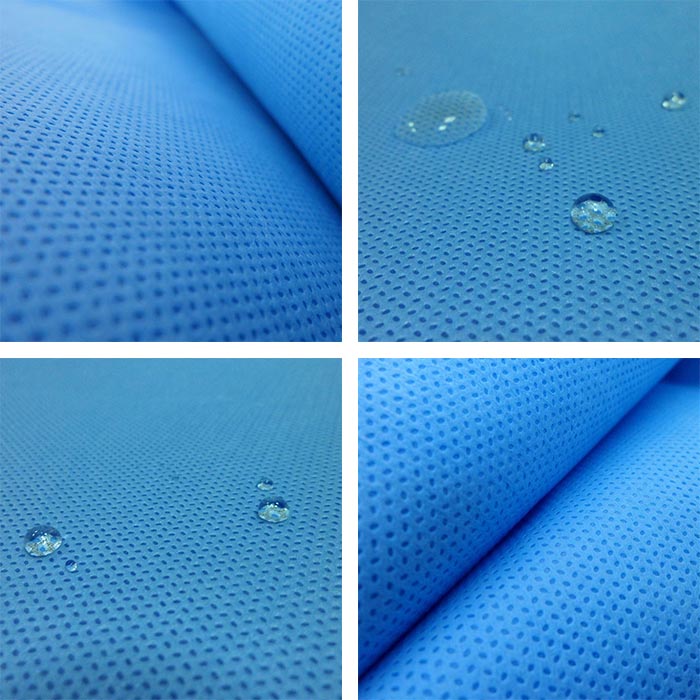

SMS non woven fabric is a combination of two processes and production of spun-bonded and melt-blown. The spun-bonded non woven fabric has high strength, poor vertical and horizontal strength, poor performance and melt-blown non woven fabric with high shielding The waterproof performance is concentrated on one material, which has the advantages of strong waterproof performance, good air permeability and effective isolation performance, which can effectively cut off the penetration of bacteria and penetrate into the blood.

SMS non woven products can effectively prevent cross infection between doctors and patients, and protect the health of medical staff. In terms of price and isolation performance, SMS has many advantages over spunlace medical materials. In recent years, more modular composite technologies have been developed, such as SMMS, SSMMS, etc., to form multi-layer composite materials, thereby improving product quality while increasing output.

For spunbond/meltblown nonwoven fabric composites, the surface layer (spunbond layer) determines the feel, and the inner layer (meltblown layer) improves shielding and filterability, thereby improving spunbond/meltblown properties. The comfort, softness and high barrier properties of blow molded composite nonwoven materials are the core, which further improves the core competitiveness of my country's medical nonwovens production industry.

评论

发表评论